A round up of all the latest nanotech product, investment, production, research and policy news, 21-25 August 2017. Recent developments include cellulose nanofiber automotive components, a novel quantum dot system to improve cancer detection and a new graphene production plant opens in Australia.

NANOTECH INVESTMENT NEWS

Versum Materials and NuMat Technologies to Commercialize Next-Generation Adsorbent Technology for Delivery of Dopant Gases

Versum Materials, Inc. , a global materials supplier to the semiconductor industry, and NuMat Technologies have commercial agreement to offer a new line of products for the safe storage and delivery of dopant gases such as arsine, phosphine and boron trifluoride. The new product line is called ION-X® and is based on Metal Organic Frameworks (MOFs), which can selectively adsorb, store and safely deliver ultrahigh purity gases at sub-atmospheric pressures. ION-X® offers performance advantages over traditional carbon-based adsorbent technology used in the ion implant processes for the manufacture of semiconductor devices.

NANOTECH PRODUCT NEWS

Researchers in Japan developing cellulose nanofiber automotive components

Together with major parts suppliers such as Denso Corp. and Daikyo-Nishikawa Corp., researchers at Kyoto University are working on plastics with incorporated cellulose nanofibers for application on automotive components for Toyota. The cellulose nanofibers are developed using the “Kyoto process,” under which chemically treated wood fibers are kneaded into plastics while they are simultaneously being broken down into the nanofibers. The method slashes the cost of production to roughly one-fifth that of other processes.

“This is the lowest-cost, highest-performance application for cellulose nanofibers, and that’s why we’re focusing on its use in auto and aircraft parts,” said Kyoto University professor Hiroaki Yano.

NANOMEDICINE NEWS

Researchers develop novel quantum dot system to improve cancer detection

Researchers at Sanford Burnham Prebys Medical Discovery Institute (SBP) have developed a proof-of-concept nanosystem that dramatically improves the visualization of tumors. The platform achieves a five-fold increase over existing tumor-specific optical imaging methods. The novel approach generates bright tumor signals by delivering “quantum dots” to cancer cells without any toxic effects.

Xiangyou Liu, Ph.D., and Gary Braun, Ph.D., developed the method in the laboratories of Kazuki Sugahara, M.D., Ph.D., adjunct assistant professor at SBP and adjunct associate research scientist at Columbia University, and Erkki Ruoslahti, M.D., Ph.D., distinguished professor at SBP.

“Tumor imaging is an integral part of cancer detection, treatment and tracking the progress of patients after treatment,” says Sugahara. “Although significant progress has been made in the last two decades, better and more sensitive detection, such as the method we are developing, will contribute to more personalized and potentially more effective interventions to improve the clinical outcomes of cancer patients.”

The new method utilizes quantum dots, QDs–tiny particles that emit intense fluorescent signals when exposed to light–and an “etchant” that eliminates background signals. The QDs are delivered intravenously, and some of them leave the bloodstream and cross membranes, entering cancer cells. Fluorescent signals emitted from excess QDs that remain in the bloodstream are then made invisible by injecting the etchant.

A new company is in the process of being founded to further develop the platform for human use.

Nanoparticle medical company sign deal with pharma company

Evotec’s immunology spin-out Topas Therapeutics hassigned a multi-year R&D collaboration with pharmaceutical multinational Eli Lilly. The initial focus of research, which will be financed by Eli Lilly, is on identification of antigens that specifically induce a T regulatory cell response in inflammatory and auto-immune disorders.

Using the company’s nanoparticle platform, the collaboration will initially focus on identification of inflammatory or autoimmunity-inducing antigens that trigger immune tolerance through activation of regulatory T cells responses in liver stem cells. Specifically, Topas targets peptide-loaded nanoparticles towards liver sinusoidal endothelial cells (LSECs), which are one of the body’s premier sites to induce tolerance against bloodborne antigens by generating peptide-specific regulatory T cells.

QUANTUM DOTS NEWS

Nanoco Group plc a developer and manufacturer of cadmium-free quantum dots (“CFQD”) and other nanomaterials, provides the following trading update ahead of its preliminary results for the year ended 31 July 2017. It has been a significant year for the Group with solid advances towards the commercialisation of its technology. Unaudited revenues in the year and net cash at the year end were in line with the Board’s expectations. Highlights in the year included:

- The Group’s first commercial orders – to supply CFQD resin to global manufacturer Wah Hong

- New routes to market established for CFQDs in Display

- TVs using Nanoco CFQD® Fine Color Film™ exhibited at CES in January 2017

- Runcorn manufacturing facility became commercially viable

- A growing pipeline of potential Display business

- Progress in Life Sciences and Lighting markets

GRAPHENE PRODUCT NEWS

UK graphene producer signs composites agreement

Haydale has agreed terms for a technical and commercial collaboration with Rogers Advanced Composites Ltd (“RAC”) to develop graphene in composites, polymers and resins. RAC which has roots in the marine and yachting world, through its sister company Rogers Yacht Design, has built a strong reputation in the design and manufacture of advanced composite products. It is Haydale’s understanding that RAC is experiencing a strong demand for high quality composite solutions across a range of industrial sectors including marine, military and motor sport and that RAC is in the process of securing long term production contracts for an oil recovery project as well as several aerospace, military and motor racing projects. There are also some prospects in the rail and shipping sectors as well as new build high performance carbon fibre race boats and refits.

GRAPHENE PRODUCTION NEWS

New graphene production plants opens in Australia

Imagine Intelligent Materials Pty Ltd. has opened a graphene manufacturing plant in Geelong. Craig Laundy, the Federal Assistant Minister for Industry, formally opened Imagine Intelligent Materials’ new graphene factory in Geelong. “Imagine IM has demonstrated a capacity to both develop and manufacture highly effective end products which have revolutionary implications for manufacturing industries in Australia,” said Laundy at the launch. Laundy added that they were, “a great example of a regional manufacturer whose cutting-edge work was having an impact beyond the region.”

The Australian Advanced Manufacturing Growth Centre announced a $250,000 grant to co-fund projects commercialising graphene at an industrially-relevant scale. “I view our commitment as a signal to Australian industry that this new generation of materials is where we can boost our impact in global competitiveness,” said the AMGC’s Managing Director, Dr Jens Goennemann.

“Smart graphene-coated geotextiles that can be used to line dams and report on leaks are already being used in Australia. These are the tip of the iceberg. Imagine how much more competitive the mining industry will become as these smart textiles become part of massive real-time sensing networks, able to report on the structural integrity of a dam wall.”

Imagine Intelligent Materials’ David Rieser talks with Assistant Minister Craig Laundy at the opening. Picture: Alison Wynd

Imagine Intelligent Materials Pty Ltd., has also announced that Pacific American Coal Ltd (PAK) has sold its 30% stake in Imagine IM to a new investment group.

Graphene-enhanced geotextile installation

GRAPHENE RESEARCH NEWS

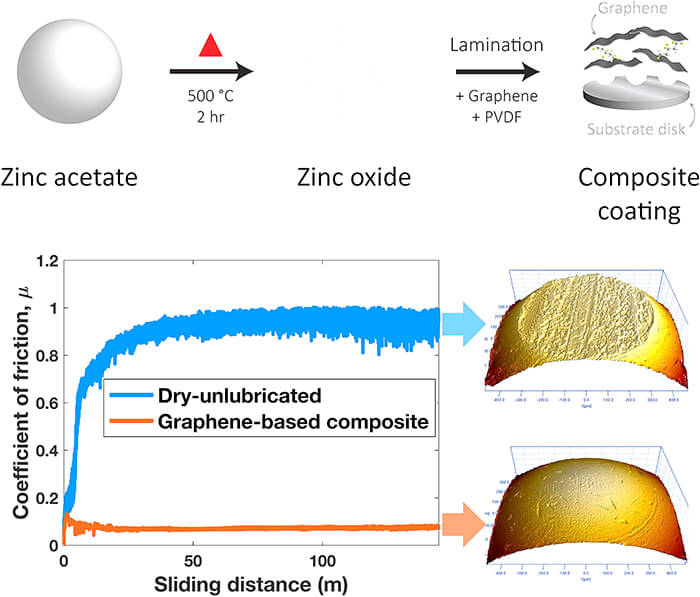

Graphene solid lubricant shown to reduce friction and wear on steel surfaces

Researchers from Purdue University have created a new type of non-liquid lubricant that has been shown to reduce friction and wear significantly under the extreme conditions found in various applications, from air compressors to missile systems. The new liquid-free composite is made from a slurry of a material called graphene, zinc oxide, and the polymer polyvinylidene difluoride. Read more at http://www.sciencedirect.com/science/article/pii/S0008622317307133

This composite image depicts the makeup and performance of a new non-liquid lubricant developed by researchers at Purdue University. (Purdue University image/ Abdullah A. Alazemi) Download image

2-faced 2-D material is a first at Rice

Like a sandwich with wheat on the bottom and rye on the top, Rice University scientists have cooked up a tasty new twist on two-dimensional materials. The Rice laboratory of materials scientist Jun Lou has made a semiconducting transition-metal dichalcogenide (TMD) that starts as a monolayer of molybdenum diselenide. They then strip the top layer of the lattice and replace precisely half the selenium atoms with sulfur. The new material they call Janus sulfur molybdenum selenium (SMoSe) has a crystalline construction the researchers said can host an intrinsic electric field and that also shows promise for catalytic production of hydrogen. Read more at http://pubs.acs.org/doi/abs/10.1021/acsnano.7b03186

Rice materials scientists replace all the atoms on top of a three-layer, two-dimensional crystal to make a transition-metal dichalcogenide with sulfur, molybdenum and selenium. Click on the image for a larger version. Illustration by Jing Zhang

Graphene enabled highly reversible aluminum-ion batteries

Researchers at Clemson University have designed a prototype Aluminum-ion battery (AIB) that uses a graphene electrode to intercalate tetrachloroaluminate (AlCl4–). The researchers have used the device to investigate the effect of defects and doping on battery performance. Aluminum-ion batteries are increasingly considered as a possible alternative to Li-ion battery systems, but so far the element has been difficult to study. Unlike in LIBs, where the mobile ion is Li+, aluminum forms a complex with chloride in most electrolytes and generates an anionic mobile charge carrier, usually AlCl4– or Al2Cl7–. Writing in Nano Energy, Anthony Childress and colleagues at Clemson University’s Clemson Nanomaterials Institute have elucidated the intercalation mechanism of the AlCl4– anion in graphene electrodes, and provided a unique insight into the influence of defects and doping on the intercalation process.

Meter-sized single-crystal graphene growth becomes possible

Since the discovery of graphene, the synthesis of graphene has long been a hot spot in graphene community. Using transition metals such as Cu or Ni as substrate, scientists have realized the preparation of large-area graphene films. Especially, high-quality large-scale continuous monolayer graphene has been successfully grown on Cu foils. This simple and low-cost method has been widely accepted as the most promising way for industrial-level graphene production. However, graphene films obtained by this method are usually polycrystalline with domain boundaries, which would greatly degrade the electrical, mechanical, thermal and optical properties. Therefore, to find a method to synthesize large-size single-crystal graphene is a big scientific problem needed to be solved.

Prof. K. H. Liu, Prof. D. P. Yu and Prof. E. G. Wang from Peking University cooperating with Prof. F. Ding from Ulsan National Institute of Science and Technology and other collaborators found a new way to prepare 5×50 cm2 single-crystal graphene on industrial Cu foils. They first transformed industrial polycrystalline Cu foils into single-crystal Cu(111) by thermal annealing using a temperature-gradient-driving technique. Graphene domains were epitaxially grown on the Cu(111) substrate and then seamlessly merged together to form a large single-crystal graphene films. Combined with their ultrafast graphene growth technique, the graphene growth rate and each individual graphene domain size were improved obviously. Also, oxygen released from oxide at high temperature was proved to further improve the domain alignment, which would greatly improve the quality of graphene films. Read more at http://www.sciencedirect.com/science/article/pii/S209592731730350X and http://www.nature.com/nnano/journal/v11/n11/full/nnano.2016.132.html?foxtrotcallback=true

These are schematic diagrams for epitaxial growth of single-crystal graphene on industrial Cu foil.